Just about every electronic device contains a transformer. Transformers convert the standard voltage from the wall outlet into the lower voltages required by the electronic device. One of the important materials they consist of is electrical steel. Researchers have found a way to improve the performance of electrical steel and manufacture it more efficiently, using an optimized laser process.

Similar, but more powerful, transformers are used in electricity substations to convert the high voltages of the transmission grid into the standard alternating current (AC) power supply delivered to households.

All transformers have the same basic structure: a pair of iron cores, around which wires of different lengths are wrapped. These are the transformer coils, one of which generates an oscillating magnetic field, while the other converts this magnetic field into a voltage.

To minimize the energy loss associated with this process, special types of iron-silicon alloy known as electrical steel are used to make the core. In their native state, these alloys have grain-oriented structure which determines their magnetic properties.

The term grain-oriented means that the material has a crystalline structure in which each crystal, or grain, is arranged in a regular periodic order. “By heating selected areas of the material, its possible to reduce the size of the domains with the same magnetic orientation, which in turn alters the magnetic structure of the steel. This results in a lower heat development and thus reduces the material’s hysteresis loss,” says Dr. Andreas Wetzig, who heads the laser ablation and cutting department at the Fraunhofer Institute for Material and Beam Technology IWS in Dresden.

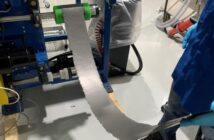

Laser processing has long become established as the preferred method for this type of heat treatment. While the steel sheet, measuring around one meter in width, moves forward at a rate of more than 100 meters per minute, a focused laser beam travels at very high speed (approximately 200 meters per second) from side to side across the surface of the material along paths spaced a few millimeters apart.

The Dresden-based research team has optimized this process: “We have developed a means of deflecting the laser beam that allows the distance between the paths to be controlled flexibly and adapted to different parameters,” states Wetzig. The researchers make use of galvanometer scanners to do so.

These devices consist of galvanometer driven mirrors attached to one end, which is used to deflect the laser beam. This increases the flexibility of the machining process and allows it to be adapted to specific conditions, such as the quality of the raw material, and to different production rates. The researches main goal is to facilitate the integration of laser processing in existing production environments, in order to save time and costs.

In a further effort to reduce hysteresis loss in electrical steel, the researchers have recently started working with a new type of solid-state laser: the fiber laser. “The results we have obtained so far are very promising. This type of laser offers better heat absorption characteristics than traditional CO2 lasers,” says Wetzig. It cuts hysteresis loss by up to 15 percent, compared with the 10 percent normally achieved until now. The optimized process is currently being implemented by the first commercial customer.

At UPS Battery Center, our goal isn’t to only sell batteries, we want to inform and teach you about the amazing world of batteries, electricity and energy. Please check back for more interesting, helpful and informative articles about batteries and electricity.

Related Articles:

5 Things to Know About Tesla Coils

Basic Principles of an Alternating Current (AC)